Sheet Metal Fabrication

From Flat Sheets to Flawless Forms — Fast & Precise.

Bending

- High Precision

- Cost-Effective

- Material Efficiency

- Versatility

Forming

- Complex Shapes

- High Strength Retention

- Smooth Finishes

- Mass Production

Cutting

- High Accuracy

- Flexibility

- Fast Production

- Minimal Distortion

Introduction

Sheet Metal Services

Sheet metal services encompass a range of manufacturing processes designed to cut, bend, form, and assemble metal sheets into functional components and structures. Using advanced techniques such as laser cutting, CNC bending, stamping, welding, and assembly, these services deliver high-precision parts for industries like automotive, aerospace, construction, electronics, and HVAC.

Key Capabilities Include:

- Cutting: Laser, plasma, and waterjet cutting for intricate designs with tight tolerances.

- Bending: CNC press brakes for accurate angles and complex geometries.

- Forming: Stamping, deep drawing, and roll forming for custom shapes.

- Finishing: Deburring, powder coating, anodizing, and polishing for enhanced durability.

- Assembly: Welding, riveting, and fastening for complete fabricated solutions.

Whether for prototyping, custom fabrication, or large-scale production, sheet metal services offer cost-effective, durable, and high-performance solutions tailored to meet stringent industry standards.

Incredibe Extremely

Easy to Collaborate with Globally, and Delivers Your Parts on Time.

A reliable partner that makes collaboration effortless and delivers precision parts on time, every time.

Case Studies

Parts & Products

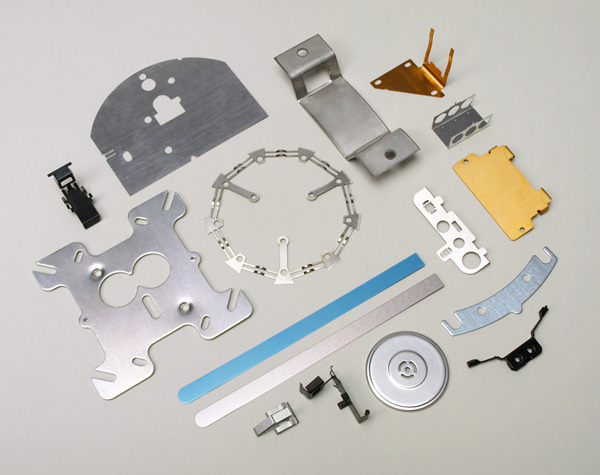

Beyond these sheet metal fabrication examples, we possess an extensive portfolio showcasing our advanced forming capabilities, precision engineering, and cross-industry expertise. Our proven track record includes complex projects in aerospace structural components, automotive chassis systems, and industrial machinery enclosures—each manufactured to meet stringent tolerances, durability standards, and custom specifications.

From laser-cut prototypes to high-volume stamped production runs, we combine state-of-the-art equipment with deep material knowledge (aluminum, stainless steel, specialty alloys) to deliver solutions that perform.